Section 5

Inventory Management

By Boundless

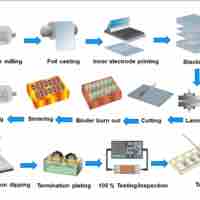

Most manufacturing organizations usually divide their inventory into raw materials, work in process, finished goods, and goods for sales.

FIFO, LIFO, and average cost methods are accounting techniques used in managing inventory.

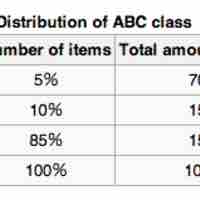

The ABC analysis is an inventory categorization technique often used in material management wherein accuracy and control decreases from A to C.

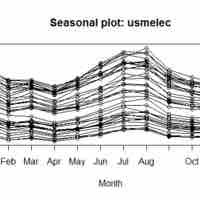

Seasonal trends and internal projections of consumption in certain goods can have a significant impact on opportunity cost and potential profit for an organization.

High inflation encourages companies to keep a high level of inventories.

Inventory costs depends on methods used, which include Specific Identification, Weighted Average Cost, Moving-Average Cost, FIFO, and LIFO.

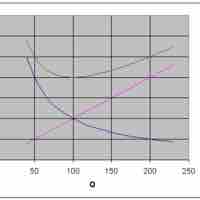

Economic order quantity is the order quantity that minimizes total inventory holding costs and ordering costs:

Just in time (JIT) is a production strategy that strives to reduce in-process inventory and carrying costs in a manufacturing system.

Improved inventory management can lead to increased revenue, lower handling and holding costs, and improved cash flows.

Excessive inventory means idle funds which earn no profits; inadequate inventory means lost sales.