Glass

Did you know...

The articles in this Schools selection have been arranged by curriculum topic thanks to SOS Children volunteers. Do you want to know about sponsoring? See www.sponsorachild.org.uk

Glass is an amorphous (non-crystalline) solid material that exhibits a glass transition. Glasses are typically brittle and can be optically transparent.

The most familiar type of glass, used for centuries in windows and drinking vessels, is soda-lime glass, composed of about 75% silica (SiO2) plus sodium oxide (Na2O) from soda ash, lime (CaO), and several minor additives. Often, the term glass is used in a restricted sense to refer to this specific use.

In science, however, the term glass is usually defined in a much wider sense, including every solid that possesses a non-crystalline (i.e. amorphous) structure and that exhibits a glass transition when heated towards the liquid state. In this wider sense, glasses can be made of quite different classes of materials: metallic alloys, ionic melts, aqueous solutions, molecular liquids, and polymers. For many applications ( bottles, eyewear) polymer glasses ( acrylic glass, polycarbonate, polyethylene terephthalate) are a lighter alternative to traditional silica glasses.

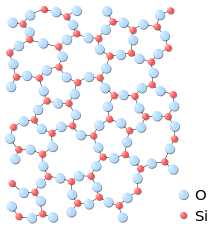

Silicate glass

Silica (the chemical compound SiO2) is a common fundamental constituent of glass. In nature, vitrification of quartz occurs when lightning strikes sand, forming hollow, branching rootlike structures called fulgurite.

History

The history of creating glass can be traced back to 3500 BCE in Mesopotamia. The term glass developed in the late Roman Empire. It was in the Roman glassmaking centre at Trier, now in modern Germany, that the late-Latin term glesum originated, probably from a Germanic word for a transparent, lustrous substance.

Glass ingredients

While fused quartz (primarily composed of SiO2) is used for some special applications, it is not very common due to its high glass transition temperature of over 1200 °C (2192 °F). Normally, other substances are added to simplify processing. One is sodium carbonate (Na2CO3, "soda"), which lowers the glass transition temperature. However, the soda makes the glass water soluble, which is usually undesirable, so lime ( calcium oxide [CaO], generally obtained from limestone), some magnesium oxide (MgO) and aluminium oxide (Al2O3) are added to provide for a better chemical durability. The resulting glass contains about 70 to 74% silica by weight and is called a soda-lime glass. Soda-lime glasses account for about 90% of manufactured glass.

Most common glass contains other ingredients added to change its properties. Lead glass or flint glass is more 'brilliant' because the increased refractive index causes noticeably more specular reflection and increased optical dispersion. Adding barium also increases the refractive index. Thorium oxide gives glass a high refractive index and low dispersion and was formerly used in producing high-quality lenses, but due to its radioactivity has been replaced by lanthanum oxide in modern eye glasses. Iron can be incorporated into glass to absorb infrared energy, for example in heat absorbing filters for movie projectors, while cerium(IV) oxide can be used for glass that absorbs UV wavelengths.

The following is a list of the more common types of silicate glasses, and their ingredients, properties, and applications:

- Fused silica glass, vitreous silica glass: silica (SiO2). Has very low thermal expansion, is very hard and resists high temperatures (1000–1500 °C). It is also the most resistant against weathering (alkali ions leaching out of the glass, while staining it). It is used for high temperature applications such as furnace tubes, melting crucibles, etc.

- Soda-lime-silica glass, window glass: silica 72% + sodium oxide (Na2O) 14.2% + magnesia (MgO) 2.5% + lime (CaO) 10.0% + alumina (Al2O3) 0.6%. Is transparent, easily formed and most suitable for window glass. It has a high thermal expansion and poor resistance to heat (500–600 °C). Used for windows, containers, light bulbs, tableware.

- Sodium borosilicate glass, Pyrex: silica 81% + boric oxide (B2O3) 12% + soda (Na2O) 4.5% + alumina (Al2O3) 2.0%. Stands heat expansion much better than window glass. Used for chemical glassware, cooking glass, car head lamps, etc. Borosilicate glasses (e.g. Pyrex) have as main constituents silica and boron oxide. They have fairly low coefficients of thermal expansion (7740 Pyrex CTE is 3.25×10–6/°C as compared to about 9×10−6/°C for a typical soda-lime glass), making them more dimensionally stable. The lower CTE also makes them less subject to stress caused by thermal expansion, thus less vulnerable to cracking from thermal shock. They are commonly used for reagent bottles, optical components and household cookware.

- Lead-oxide glass, crystal glass: silica 59% + soda (Na2O) 2.0% + lead oxide (PbO) 25% + potassium oxide (K2O) 12% + alumina 0.4% + zinc oxide (ZnO) 1.5%. Has a high refractive index, making the look of glassware more brilliant (crystal glass). It also has a high elasticity, making glassware 'ring'. It is also more workable in the factory, but cannot stand heating very well.

- Aluminosilicate glass: silica 57% + alumina 16% + boric oxide (B2O3) 4.0% + barium oxide (BaO) 6.0% + magnesia 7.0% + lime 10%. Extensively used for fibreglass, used for making glass-reinforced plastics (boats, fishing rods, etc.). Also for halogen bulb glass.

- Oxide glass: alumina 90% + germanium oxide (GeO2) 10%. Extremely clear glass, used for fiber-optic wave guides in communication networks. Light loses only 5% of its intensity through 1 km of glass fibre.

Another common glass ingredient is "cullet" ( recycled glass). The recycled glass saves on raw materials and energy; however, impurities in the cullet can lead to product and equipment failure.

Fining agents such as sodium sulfate, sodium chloride, or antimony oxide may be added to reduce the number of air bubbles in the glass mixture. Glass batch calculation is the method by which the correct raw material mixture is determined to achieve the desired glass composition.

Contemporary glass production

Following the glass batch preparation and mixing, the raw materials are transported to the furnace. Soda-lime glass for mass production is melted in gas fired units. Smaller scale furnaces for specialty glasses include electric melters, pot furnaces, and day tanks.

After melting, homogenization and refining (removal of bubbles), the glass is formed. Flat glass for windows and similar applications is formed by the float glass process, developed between 1953 and 1957 by Sir Alastair Pilkington and Kenneth Bickerstaff of the UK's Pilkington Brothers, who created a continuous ribbon of glass using a molten tin bath on which the molten glass flows unhindered under the influence of gravity. The top surface of the glass is subjected to nitrogen under pressure to obtain a polished finish. Container glass for common bottles and jars is formed by blowing and pressing methods. Further glass forming techniques are summarized in the table Glass forming techniques.

Once the desired form is obtained, glass is usually annealed for the removal of stresses. Surface treatments, coatings or lamination may follow to improve the chemical durability ( glass container coatings, glass container internal treatment), strength ( toughened glass, bulletproof glass, windshields), or optical properties ( insulated glazing, anti-reflective coating).

Architecture

The use of glass in buildings is a transparent feature to allow light to enter into rooms and floors, illuminating enclosed spaces and framing an exterior view through a window. It is also a material for internal partitions and external cladding.

Glassmaking in the laboratory

New chemical glass compositions or new treatment techniques can be initially investigated in small-scale laboratory experiments. The raw materials for laboratory-scale glass melts are often different from those used in mass production because the cost factor has a low priority. In the laboratory mostly pure chemicals are used. Care must be taken that the raw materials have not reacted with moisture or other chemicals in the environment (such as alkali or alkaline earth metal oxides and hydroxides, or boron oxide), or that the impurities are quantified (loss on ignition). Evaporation losses during glass melting should be considered during the selection of the raw materials, e.g., sodium selenite may be preferred over easily evaporating SeO2. Also, more readily reacting raw materials may be preferred over relatively inert ones, such as Al(OH)3 over Al2O3. Usually, the melts are carried out in platinum crucibles to reduce contamination from the crucible material. Glass homogeneity is achieved by homogenizing the raw materials mixture ( glass batch), by stirring the melt, and by crushing and re-melting the first melt. The obtained glass is usually annealed to prevent breakage during processing.

In order to make glass from materials with poor glass forming tendencies, novel techniques are used to increase cooling rate, or reduce crystal nucleation triggers. Examples of these techniques include aerodynamic levitation (cooling the melt whilst it floats on a gas stream), splat quenching (pressing the melt between two metal anvils) and roller quenching (pouring the melt through rollers).

See also: Optical lens design, Fabrication and testing of optical components

Other glasses

Network glasses

Some glasses that do not include silica as a major constituent may have physico-chemical properties useful for their application in fibre optics and other specialized technical applications. These include fluoride glasses, aluminosilicates, phosphate glasses, borate glasses, and chalcogenide glasses.

There are three classes of components for oxide glasses: network formers, intermediates, and modifiers. The network formers (silicon, boron, germanium) form a highly cross-linked network of chemical bonds. The intermediates (titanium, aluminium, zirconium, beryllium, magnesium, zinc) can act as both network formers and modifiers, according to the glass composition. The modifiers (calcium, lead, lithium, sodium, potassium) alter the network structure; they are usually present as ions, compensated by nearby non-bridging oxygen atoms, bound by one covalent bond to the glass network and holding one negative charge to compensate for the positive ion nearby. Some elements can play multiple roles; e.g. lead can act both as a network former (Pb4+ replacing Si4+), or as a modifier.

The presence of non-bridging oxygens lowers the relative number of strong bonds in the material and disrupts the network, decreasing the viscosity of the melt and lowering the melting temperature.

The alkali metal ions are small and mobile; their presence in glass allows a degree of electrical conductivity, especially in molten state or at high temperature. Their mobility, however, decreases the chemical resistance of the glass, allowing leaching by water and facilitating corrosion. Alkaline earth ions, with their two positive charges and requirement for two non-bridging oxygen ions to compensate for their charge, are much less mobile themselves and also hinder diffusion of other ions, especially the alkalis. The most common commercial glasses contain both alkali and alkaline earth ions (usually sodium and calcium), for easier processing and satisfying corrosion resistance. Corrosion resistance of glass can be achieved by dealkalization, removal of the alkali ions from the glass surface by reaction with e.g. sulfur or fluorine compounds. Presence of alkaline metal ions has also detrimental effect to the loss tangent of the glass, and to its electrical resistance; glasses for electronics (sealing, vacuum tubes, lamps...) have to take this in account.

Addition of lead(II) oxide lowers melting point, lowers viscosity of the melt, and increases refractive index. Lead oxide also facilitates solubility of other metal oxides and therefore is used in colored glasses. The viscosity decrease of lead glass melt is very significant (roughly 100 times in comparison with soda glasses); this allows easier removal of bubbles and working at lower temperatures, hence its frequent use as an additive in vitreous enamels and glass solders. The high ionic radius of the Pb2+ ion renders it highly immobile in the matrix and hinders the movement of other ions; lead glasses therefore have high electrical resistance, about two orders of magnitude higher than soda-lime glass (108.5 vs 106.5 Ohm·cm, DC at 250 °C). For more details, see lead glass.

Addition of fluorine lowers the dielectric constant of glass. Fluorine is highly electronegative and attracts the electrons in the lattice, lowering the polarizability of the material. Such silicon dioxide-fluoride is used in manufacture of integrated circuits as an insulator. High levels of fluorine doping lead to formation of volatile SiF2O and such glass is then thermally unstable. Stable layers were achieved with dielectric constant down to about 3.5–3.7.

Amorphous metals

In the past, small batches of amorphous metals with high surface area configurations (ribbons, wires, films, etc.) have been produced through the implementation of extremely rapid rates of cooling. This was initially termed "splat cooling" by doctoral student W. Klement at Caltech, who showed that cooling rates on the order of millions of degrees per second is sufficient to impede the formation of crystals, and the metallic atoms become "locked into" a glassy state. Amorphous metal wires have been produced by sputtering molten metal onto a spinning metal disk. More recently a number of alloys have been produced in layers with thickness exceeding 1 millimeter. These are known as bulk metallic glasses (BMG). Liquidmetal Technologies sell a number of zirconium-based BMGs. Batches of amorphous steel have also been produced that demonstrate mechanical properties far exceeding those found in conventional steel alloys.

In 2004, NIST researchers presented evidence that an isotropic non-crystalline metallic phase (dubbed "q-glass") could be grown from the melt. This phase is the first phase, or "primary phase," to form in the Al-Fe-Si system during rapid cooling. Interestingly, experimental evidence indicates that this phase forms by a first-order transition. Transmission electron microscopy (TEM) images show that the q-glass nucleates from the melt as discrete particles, which grow spherically with a uniform growth rate in all directions. The diffraction pattern shows it to be an isotropic glassy phase. Yet there is a nucleation barrier, which implies an interfacial discontinuity (or internal surface) between the glass and the melt.

Electrolytes

Electrolytes or molten salts are mixtures of different ions. In a mixture of three or more ionic species of dissimilar size and shape, crystallization can be so difficult that the liquid can easily be supercooled into a glass. The best studied example is Ca0.4K0.6(NO3)1.4.

Aqueous solutions

Some aqueous solutions can be supercooled into a glassy state, for instance LiCl:RH2O in the composition range 4<R<8.

Molecular liquids

A molecular liquid is composed of molecules that do not form a covalent network but interact only through weak van der Waals forces or through transient hydrogen bonds. Many molecular liquids can be supercooled into a glass; some are excellent glass formers that normally do not crystallize.

A widely known example is sugar glass.

Under extremes of pressure and temperature solids may exhibit large structural and physical changes that can lead to polyamorphic phase transitions. In 2006 Italian scientists created an amorphous phase of carbon dioxide using extreme pressure. The substance was named amorphous carbonia(a-CO2) and exhibits an atomic structure resembling that of silica.

Polymers

Colloidal glasses

Concentrated colloidal suspensions may exhibit a distinct glass transition as function of particle concentration or density.

Glass-ceramics

Glass-ceramic materials share many properties with both non-crystalline glass and crystalline ceramics. They are formed as a glass, and then partially crystallized by heat treatment. For example, the microstructure of whiteware ceramics frequently contains both amorphous and crystalline phases. Crystalline grains are often embedded within a non-crystalline intergranular phase of grain boundaries. When applied to whiteware ceramics, vitreous means the material has an extremely low permeability to liquids, often but not always water, when determined by a specified test regime.

The term mainly refers to a mix of lithium and aluminosilicates that yields an array of materials with interesting thermomechanical properties. The most commercially important of these have the distinction of being impervious to thermal shock. Thus, glass-ceramics have become extremely useful for countertop cooking. The negative thermal expansion coefficient (CTE) of the crystalline ceramic phase can be balanced with the positive CTE of the glassy phase. At a certain point (~70% crystalline) the glass-ceramic has a net CTE near zero. This type of glass-ceramic exhibits excellent mechanical properties and can sustain repeated and quick temperature changes up to 1000 °C.

Structure

As in other amorphous solids, the atomic structure of a glass lacks any long-range translational periodicity. However, due to chemical bonding characteristics glasses do possess a high degree of short-range order with respect to local atomic polyhedra.

Glass versus supercooled liquid

In physics, the standard definition of a glass (or vitreous solid) is a solid formed by rapid melt quenching. However, the term glass is often used to describe any amorphous solid that exhibits a glass transition temperature Tg. If the cooling is sufficiently rapid (relative to the characteristic crystallization time) then crystallization is prevented and instead the disordered atomic configuration of the supercooled liquid is frozen into the solid state at Tg. Generally, the structure of a glass exists in a metastable state with respect to its crystalline form, although in certain circumstances, for example in atactic polymers, there is no crystalline analogue of the amorphous phase.

Some people consider glass to be a liquid due to its lack of a first-order phase transition where certain thermodynamic variables such as volume, entropy and enthalpy are discontinuous through the glass transition range. However, the glass transition may be described as analogous to a second-order phase transition where the intensive thermodynamic variables such as the thermal expansivity and heat capacity are discontinuous. Despite this, the equilibrium theory of phase transformations does not entirely hold for glass, and hence the glass transition cannot be classed as one of the classical equilibrium phase transformations in solids.

| What is the nature of the transition between a fluid or regular solid and a glassy phase? "The deepest and most interesting unsolved problem in solid state theory is probably the theory of the nature of glass and the glass transition." P.W. Anderson |

Glass is an amorphous solid. It exhibits an atomic structure close to that observed in the supercooled liquid phase but displays all the mechanical properties of a solid. The notion that glass flows to an appreciable extent over extended periods of time is not supported by empirical research or theoretical analysis (see viscosity of amorphous materials). Laboratory measurements of room temperature glass flow do show a motion consistent with a material viscosity on the order of 1017–1018 Pa s.

Although the atomic structure of glass shares characteristics of the structure in a supercooled liquid, glass tends to behave as a solid below its glass transition temperature. A supercooled liquid behaves as a liquid, but it is below the freezing point of the material, and in some cases will crystallize almost instantly if a crystal is added as a core. The change in heat capacity at a glass transition and a melting transition of comparable materials are typically of the same order of magnitude, indicating that the change in active degrees of freedom is comparable as well. Both in a glass and in a crystal it is mostly only the vibrational degrees of freedom that remain active, whereas rotational and translational motion is arrested. This helps to explain why both crystalline and non-crystalline solids exhibit rigidity on most experimental time scales.

Behaviour of antique glass

The observation that old windows are sometimes found to be thicker at the bottom than at the top is often offered as supporting evidence for the view that glass flows over a timescale of centuries. The assumption being that the glass was once uniform, but has flowed to its new shape, which is a property of liquid. However, this assumption is incorrect; once solidified, glass does not flow anymore. The reason for the observation is that in the past, when panes of glass were commonly made by glassblowers, the technique used was to spin molten glass so as to create a round, mostly flat and even plate (the crown glass process, described above). This plate was then cut to fit a window. The pieces were not, however, absolutely flat; the edges of the disk became a different thickness as the glass spun. When installed in a window frame, the glass would be placed with the thicker side down both for the sake of stability and to prevent water accumulating in the lead cames at the bottom of the window. Occasionally such glass has been found thinner side down or thicker on either side of the window's edge, the result of carelessness during installation.

Mass production of glass window panes in the early twentieth century caused a similar effect. In glass factories, molten glass was poured onto a large cooling table and allowed to spread. The resulting glass is thicker at the location of the pour, located at the centre of the large sheet. These sheets were cut into smaller window panes with nonuniform thickness, typically with the location of the pour centered in one of the panes (known as "bull's-eyes") for decorative effect. Modern glass intended for windows is produced as float glass and is very uniform in thickness.

Several other points can be considered that contradict the "cathedral glass flow" theory:

- Writing in the American Journal of Physics, materials engineer Edgar D. Zanotto states "... the predicted relaxation time for GeO2 at room temperature is 1032 years. Hence, the relaxation period (characteristic flow time) of cathedral glasses would be even longer." (1032 years is many times longer than the estimated age of the Universe.)

- If medieval glass has flowed perceptibly, then ancient Roman and Egyptian objects should have flowed proportionately more — but this is not observed. Similarly, prehistoric obsidian blades should have lost their edge; this is not observed either (although obsidian may have a different viscosity from window glass).

- If glass flows at a rate that allows changes to be seen with the naked eye after centuries, then the effect should be noticeable in antique telescopes. Any slight deformation in the antique telescopic lenses would lead to a dramatic decrease in optical performance, a phenomenon that is not observed.

- There are many examples of centuries-old glass shelving that has not bent, even though it is under much higher stress from gravitational loads than vertical window glass.

The above does not apply to materials that have a glass transition temperature close to room temperature, such as certain plastics used in daily life like polystyrene and polypropylene.

Physical properties

Optical properties

Glass is in widespread use largely due to the production of glass compositions that are transparent to visible wavelengths of light. In contrast, polycrystalline materials do not in general transmit visible light. The individual crystallites may be transparent, but their facets ( grain boundaries) reflect or scatter light resulting in diffuse reflection. Glass does not contain the internal subdivisions associated with grain boundaries in polycrystals and hence does not scatter light in the same manner as a polycrystalline material. The surface of a glass is often smooth since during glass formation the molecules of the supercooled liquid are not forced to dispose in rigid crystal geometries and can follow surface tension, which imposes a microscopically smooth surface. These properties, which give glass its clearness, can be retained even if glass is partially light-absorbing i.e. colored.

Glass has the ability to refract, reflect, and transmit light following geometrical optics, without scattering it. It is used in the manufacture of lenses and windows. Common glass has a refraction index around 1.5. According to Fresnel equations, the reflectivity of a sheet of glass is about 4% per surface (at normal incidence in air), and the transmissivity of one element (two surfaces) is about 90%. Glass also finds application in optoelectronics e.g., for light-transmitting optical fibers.

Colour

Colour in glass may be obtained by addition of electrically charged ions (or colour centers) that are homogeneously distributed, and by precipitation of finely dispersed particles (such as in photochromic glasses). Ordinary soda-lime glass appears colorless to the naked eye when it is thin, although iron(II) oxide (FeO) impurities of up to 0.1 wt% produce a green tint, which can be viewed in thick pieces or with the aid of scientific instruments. Further FeO and Cr2O3 additions may be used for the production of green bottles. Sulfur, together with carbon and iron salts, is used to form iron polysulfides and produce amber glass ranging from yellowish to almost black. A glass melt can also acquire an amber colour from a reducing combustion atmosphere. Manganese dioxide can be added in small amounts to remove the green tint given by iron(II) oxide. When used in art glass or studio glass glass is colored using closely guarded recipes that involve specific combinations of metal oxides, melting temperatures and 'cook' times. Most colored glass used in the art market is manufactured in volume by vendors who serve this market although there are some glass makers with the ability to make their own colour from raw materials.

Glass art

From the 19th century, various types of fancy glass started to become significant branches of the decorative arts. Cameo glass was revived for the first time since the Romans, initially mostly used for pieces in a neo-classical style. The Art Nouveau movement in particular made great use of glass, with René Lalique, Émile Gallé, and Daum of Nancy important names in the first French wave of the movement, producing colored vases and similar pieces, often in cameo glass, and also using lustre techniques. Louis Comfort Tiffany in America specialized in secular stained glass, mostly of plant subjects, both in panels and his famous lamps. From the 20th century, some glass artists began to class themselves as in effect sculptors working in glass, and as part of the fine arts.

Several of the most common techniques for producing glass art include: blowing, kiln-casting, fusing, slumping, pate-de-verre, flame-working, hot-sculpting and cold-working. Cold work includes traditional stained glass work as well as other methods of shaping glass at room temperature. Glass can also be cut with a diamond saw, or copper wheels embedded with abrasives, and polished to give gleaming facets; the technique used in creating Waterford crystal. Art is sometimes etched into glass via the use of acid, caustic, or abrasive substances. Traditionally this was done after the glass was blown or cast. In the 1920s a new mould-etch process was invented, in which art was etched directly into the mould, so that each cast piece emerged from the mould with the image already on the surface of the glass. This reduced manufacturing costs and, combined with a wider use of colored glass, led to cheap glassware in the 1930s, which later became known as Depression glass. As the types of acids used in this process are extremely hazardous, abrasive methods have gained popularity.

Objects made out of glass include not only traditional objects such as vessels ( bowls, vases, bottles, and other containers), paperweights, marbles, beads, but an endless range of sculpture and installation art as well. Colored glass is often used, though sometimes the glass is painted, innumerable examples exist of the use of stained glass.

Museums

Apart from historical collections in general museums, modern works of art in glass can be seen in a variety of museums, including the Chrysler Museum, the Museum of Glass in Tacoma, the Metropolitan Museum of Art, the Toledo Museum of Art, and Corning Museum of Glass, in Corning, NY, which houses the world's largest collection of glass art and history, with more than 45,000 objects in its collection. In February 2000 the Smith Museum of Stained Glass Windows, located in Chicago's Navy Pier, opened as the first museum in America dedicated solely to stained glass windows. The museum features works by Louis Comfort Tiffany and John Lafarge, and is open daily free to the public.

The Harvard Museum of Natural History has a collection of extremely detailed models of flowers made of painted glass. These were lampworked by Leopold Blaschka and his son Rudolph, who never revealed the method he used to make them. The Blaschka Glass Flowers are still an inspiration to glassblowers today.