Supply chains have become faster, cheaper, and more reliable through investment in information technology, cost-analysis, and process-analysis.

Supply chain optimization applies processes and tools that ensure optimal operation of a manufacturing and distribution supply chain. These include the optimal placement of inventory within the supply chain and the minimizing of operating costs associated with manufacturing, transportation, and distribution. Optimization may also incorporate computer-based mathematical modelling techniques .

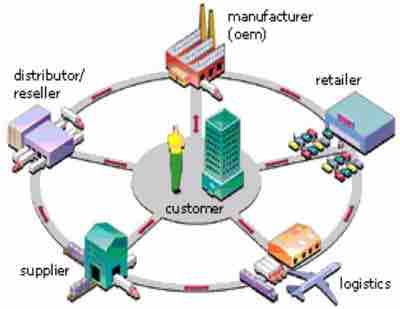

Supply Chain

Supply chain optimization applies processes and tools that ensure the optimal operation of a manufacturing and distribution supply chain.

Ongoing investment in a company's operations is necessary in order for supply chain optimization to be achieved. Supply chain managers may employ optimization such as maximizing gross margin return on inventory invested (GMROII); balancing the cost of inventory at all points in the supply chain with availability to the customer; minimizing total operating expenses (e.g., transportation, inventory, and manufacturing); and maximizing gross profit of products distributed through the supply chain.

Supply chain optimization addresses the general supply chain problem of delivering products to customers at low cost and high profit. This involves balancing the costs of inventory, transportation, distribution, and manufacturing, and supply chain optimization has applications in all industries that manufacture and/or distribute goods (retail, industrial, and/or consumer packaged goods [CPG]).

The classic supply chain approach has been to forecast future inventory demand using statistical trending and "best fit" techniques, which are based on historic demand and predicted future events. The advantage of this approach is that it can be applied to data aggregated at a fairly high level (e.g., category of merchandise; weekly, by customer category), thus requiring modest database sizes and small amounts of manipulation. Unpredictability in demand is subsequently managed by setting safety stock levels; for example, a distributor might hold two weeks of supply for a steadily in-demand article but twice that supply for an article whose demand is more erratic.

Using this forecast demand, a supply chain manufacturing and distribution plan is created to manufacture and distribute products to meet the demand at low cost and/or high profit. This plan typically addresses several questions:

- How much of each product should be manufactured each day?

- How much of each product should be made at each manufacturing plant?

- Which manufacturing plants should re-stock which warehouses with which products?

- What transportation modes should be used for warehouse replenishment and customer deliveries?

The technical ability to record and quickly manipulate large databases has allowed for the emergence of a new breed of supply chain optimization solutions, which are capable of forecasting at a granular level (for example, per article per customer per day). Some vendors are applying "best fit" models to this data, to which safety stock rules are applied, while other vendors have started to apply stochastic techniques to the optimization problem.

Supply chain optimization may include additional refinements at various stages of the product lifecycle, and new, ongoing, and obsolete items are optimized in different ways. Finally, while most software vendors are offering supply chain optimization as a packaged solution and integrated in ERP software, some vendors are running the software on behalf of clients as application service providers.