Water purification

Background to the schools Wikipedia

This wikipedia selection has been chosen by volunteers helping SOS Children from Wikipedia for this Wikipedia Selection for schools. A quick link for child sponsorship is http://www.sponsor-a-child.org.uk/

Water purification is the process of removing contaminants and other harmful microorganisms from a raw water source. The goal is to produce water for a specific purpose with a treatment profile designed to limit the inclusion of specific materials; most water is purified for human consumption (drinking water). Water purification may also be designed for a variety of other purposes, including to meet the requirements of medical, pharmacology, chemical and industrial applications. Methods include, but are not limited to: ultraviolet light, filtration, water softening, reverse osmosis, ultrafiltration, deionization and powdered activated carbon treatment.

Water purification may remove: particulate sand; suspended particles of organic material; parasites, Giardia; Cryptosporidium; bacteria; algae; viruses; fungi; minerals such as calcium, silica, and magnesium; and toxic metals like lead, copper, and chromium. Some purification may be elective in the purification process, including smell ( hydrogen sulfide remediation), taste (mineral extraction), and appearance (iron incapsulation).

Governments usually dictate the standards for drinking water quality. These standards will require minimum / maximum set points of contaminants and the inclusion of control elements that produce drinking water. Quality standards in many countries require specific amounts of disinfectant (such as chlorine) in the water after it leaves the water treatment plant (WTP), to reduce the risk of re-contamination while the water is in the distribution system.

It is not possible to tell whether water is safe to drink just by looking at it. Simple procedures such as boiling or the use of a household activated carbon filter are not sufficient for treating all the possible contaminants that may be present in water from an unknown source. Even natural spring water - considered safe for all practical purposes in the 1800s - must now be tested before determining what kind of treatment, if any, is needed. Chemical analysis, while expensive, is the only way to obtain the information necessary for deciding on method of purification.

Treatment

The processes below are the ones commonly used in water purification plants. Some or most may not be used depending on the scale of the plant and quality of the water.

Pre-treatment

- Pumping and containment - The majority of water must be pumped from its source or directed into pipes or holding tanks. To avoid adding contaminants to the water, this physical infrastructure must be made from appropriate materials and constructed so that accidental contamination does not occur.

- Screening (see also screen filter) - The first step in purifying surface water is to remove large debris such as sticks, leaves, trash and other large particles which may interfere with subsequent purification steps. Most deep groundwater does not need screening before other purification steps.

- Storage - Water from rivers may also be stored in bankside reservoirs for periods between a few days and many months to allow natural biological purification to take place. This is especially important if treatment is by slow sand filters. Storage reservoirs also provide a buffer against short periods of drought or to allow water supply to be maintained during transitory pollution incidents in the source river.

- Pre-conditioning - Many waters rich in hardness salts are treated with soda-ash ( Sodium carbonate) to precipitate calcium carbonate out utilising the common ion effect.

- Pre-chlorination - In many plants the incoming water was chlorinated to minimise the growth of fouling organisms on the pipe-work and tanks. Because of the potential adverse quality effects (see chlorine below), this has largely been discontinued.

Widely varied techniques are available to remove the fine solids, micro-organisms and some dissolved inorganic and organic materials. The choice of method will depend on the quality of the water being treated, the cost of the treatment process and the quality standards expected of the processed water.

pH adjustment

Distilled water has an average pH of 7 (neither alkaline nor acidic) and sea water has an average pH of 8.3 (slightly alkaline). If the water is acidic (lower than 7), lime or soda ash is added to raise the pH. Lime is the more common of the two additives because it is cheap, but it also adds to the resulting water hardness. Making the water slightly alkaline ensures that coagulation and flocculation processes work effectively and also helps to minimize the risk of lead being dissolved from lead pipes and lead solder in pipe fittings. If the water is alkaline, acid (HCl) and carbon dioxide (CO2) are commonly added to lower pH. Having an alkaline water does not assure that deposits on the pipe i.e. lead or copper are not released into the water. Changing the electrolytic properties of the water are more indicative to release lead or copper into the water.

Flocculation

Flocculation is a process which clarifies the water. Clarifying means removing any turbidity or colour so that the water is clear and colourless. Clarification is done by causing a precipitate to form in the water which can be removed using simple physical methods. Initially the precipitate forms as very small particles but as the water is gently stirred, these particles stick together to form bigger particles - this process is sometimes called flocculation. Many of the small particles that were originally present in the raw water absorb onto the surface of these small precipitate particles and so get incorporated into the larger particles that coagulation produces. In this way the coagulated precipitate takes most of the suspended matter out of the water and is then filtered off, generally by passing the mixture through a coarse sand filter or sometimes through a mixture of sand and granulated anthracite (high carbon and low volatiles coal). Coagulants or flocculating agents that may be used include:

-

- Iron (III) hydroxide. This is formed by adding a solution of an iron (III) compound such as iron(III) chloride to pre-treated water with a pH of 7 or greater. Iron (III) hydroxide is extremely insoluble and forms even at a pH as low as 7. Commercial formulations of iron salts were traditionally marketed in the UK under the name Cuprus.

- Aluminium hydroxide is also widely used as the flocculating precipitate although there have been concerns about possible health impacts and mis-handling led to a severe poisoning incident in 1988 at Camelford in south-west UK when the coagulant was introduced directly into the holding reservoir of final treated water.

- Aluminium hydroxychloride is an artificially produced polymer and is one of a class of synthetic polymers that are now widely used. These polymers have a high molecular weight and form very stable and readily removed flocs but tend to be more expensive in use compared to inorganic materials.

Sedimentation

Water exiting the flocculation basin may enter the sedimentation basin, also called a clarifier or settling basin. It is a large tank with slow flow, allowing floc to settle to the bottom. The sedimentation basin is best located close to the flocculation basin so the transit between does not permit settlement or floc break up. Sedimentation basins can be in the shape of a rectangle, where water flows from end to end, or circular where flow is from the centre outward. Sedimentation basin outflow is typically over a weir so only a thin top layer - furthest from the sediment - exits.The amount of floc that settles out of the water is dependent on the time the water spends in the basin and the depth of the basin. The retention time of the water must therefore be balanced against the cost of a larger basin. The minimum clarifier retention time is normally 4 hours. A deep basin will allow more floc to settle out than a shallow basin. This is because large particles settle faster than smaller ones, so large particles bump into and integrate smaller particles as they settle. In effect, large particles sweep vertically though the basin and clean out smaller particles on their way to the bottom.

As particles settle to the bottom of the basin a layer of sludge is formed on the floor of the tank. This layer of sludge must be removed and treated. The amount of sludge that is generated is significant, often 3%-5% of the total volume of water that is treated. The cost of treating and disposing of the sludge can be a significant part of the operating cost of a water treatment plant. The tank may be equipped with mechanical cleaning devices that continually clean the bottom of the tank or the tank can be taken out of service when the bottom needs to be cleaned.

Filtration

After separating most floc, the water is filtered as the final step to remove remaining suspended particles and unsettled floc. The most common type of filter is a rapid sand filter. Water moves vertically through sand which often has a layer of activated carbon or anthracite coal above the sand. The top layer removes organic compounds, which contribute to taste and odour. The space between sand particles is larger than the smallest suspended particles, so simple filtration is not enough. Most particles pass through surface layers but are trapped in pore spaces or adhere to sand particles. Effective filtration extends into the depth of the filter. This property of the filter is key to its operation: if the top layer of sand were to block all the particles, the filter would quickly clog.

To clean the filter, water is passed quickly upward through the filter, opposite the normal direction (called backflushing or backwashing) to remove embedded particles. Prior to this, compressed air may be blown up through the bottom of the filter to break up the compacted filter media to aid the backwashing process; this is known as air scouring. This contaminated water can be disposed of, along with the sludge from the sedimentation basin, or it can be recycled by mixing with the raw water entering the plant.

Some water treatment plants employ pressure filters. These work on the same principle as rapid gravity filters, differing in that the filter medium is enclosed in a steel vessel and the water is forced through it under pressure.

Advantages:

- Filters out much smaller particles than paper and sand filters can.

- Filters out virtually all particles larger than their specified pore sizes.

- They are quite thin and so liquids flow through them fairly rapidly.

- They are reasonably strong and so can withstand pressure differences across them of typically 2-5 atmospheres.

- They can be cleaned (back flushed) and reused.

Membrane filters are widely used for filtering both drinking water and sewage (for reuse). For drinking water, membrane filters can remove virtually all particles larger than 0.2 um--including Giardia and cryptosporidium. Membrane filters are an effective form of tertiary treatment when it is desired to reuse the water for industry, for limited domestic purposes, or before discharging the water into a river that is used by towns further downstream. They are widely used in industry, particularly for beverage preparation (including bottled water). However no filtration can remove substances that are actually dissolved in the water such as phosphorus, nitrates and heavy metal ions.

Slow sand filters

Slow sand filters may be used where there is sufficient land and space as the water must be passed very slowly through the filters. These filters rely on biological treatment processes for their action rather than physical filtration. The filters are carefully constructed using graded layers of sand with the coarsest sand, along with some gravel, at the bottom and finest sand at the top. Drains at the base convey treated water away for disinfection. Filtration depends on the development of a thin biological layer, called the zoogleal layer or Schmutzdecke, on the surface of the filter. An effective slow sand filter may remain in service for many weeks or even months if the pre-treatment is well designed and produces water with a very low available nutrient level which physical methods of treatment rarely achieve. Very low nutrient levels allow water to be safely sent through distribution system with very low disinfectant levels thereby reducing consumer irritation over offensive levels of chlorine and chlorine by-products. Slow sand filters are not backwashed; they are maintained by having the top layer of sand scraped off when flow is eventually obstructed by biological growth.

A specific 'large-scale' form of slow sand filter is the process of bank filtration, in which natural sediments in a riverbank are used to provide a first stage of contaminant filtration. While typically not sufficiently clean enough to be used directly for drinking water, the water gained from the associated extraction wells is much less problematic than river water taken directly from the major streams where bank filtration is often used.

Lava filters

Lava filters are similar to sand filters and may also only be used where there is sufficient land and space. Like sand filters, the filters rely on biological treatment processes for their action rather than physical filtration. Unlike slow sand filters however, they are constructed out of 2 layers of lava pebbles and a top layer of nutrient-free soil (only at the plant roots). On top, water-purifying plants (as Iris pseudacorus and Sparganium erectum) are placed. Usually, around 1/4 of the dimension of lavastone is required to purify the water and just like slow sand filters, a series of herringbone drains are placed (with lava filters these are placed at the bottom layer).

Ultrafiltration

Ultrafiltration membranes are a relatively new development; they use polymer film with chemically formed microscopic pores that can be used in place of granular media to filter water effectively without coagulants. The type of membrane media determines how much pressure is needed to drive the water through and what sizes of micro-organisms can be filtered out.

Other mechanical and biological techniques

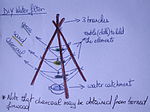

In addition to the many techniques used in large-scale water treatment, several small-scale, less (or non)-polluting techniques are also being used to treat polluted water. These techniques include those based on mechanical and biological processes. An overview:

- mechanical systems: sand filtration, lava filter systems and systems based on UV-radiation)

- biological systems:

- plant systems as constructed wetlands and treatment ponds (sometimes incorrectly called reedbeds) and living walls) and

- compact systems as activated sludge systems, biorotors, aerobic and anaerobic biofilters, submerged aerated filters, and biorolls

In order to purify the water adequately, several of these systems are usually combined to work as a whole. Combination of the systems is done in two to three stages, namely primary and secondary purification. Sometimes tertiary purification is also added.

Disinfection

Disinfection is accomplished both by filtering out harmful microbes and also by adding disinfectant chemicals in the last step in purifying drinking water. Water is disinfected to kill any pathogens which pass through the filters. Possible pathogens include viruses, bacteria, including Escherichia coli, Campylobacter and Shigella, and protozoans, including G. lamblia and other cryptosporidia. In most developed countries, public water supplies are required to maintain a residual disinfecting agent throughout the distribution system, in which water may remain for days before reaching the consumer. Following the introduction of any chemical disinfecting agent, the water is usually held in temporary storage - often called a contact tank or clear well to allow the disinfecting action to complete.

- Chlorination- The most common disinfection method is some form of chlorine or its compounds such as chloramine or chlorine dioxide. Chlorine is a strong oxidant that rapidly kills many harmful micro-organisms. Because chlorine is a toxic gas, there is a danger of a release associated with its use. This problem is avoided by the use of sodium hypochlorite, which is a relatively inexpensive solution that releases free chlorine when dissolved in water. Chlorine solutions can be generated on site by electrolyzing common salt solutions. A solid form , calcium hypochlorite exists that releases chlorine on contact with water. Handling the solid, however, requires greater routine human contact through opening bags and pouring than the use of gas cylinders or bleach which are more easily automated. The generation of liquid sodium hypochlorite is both inexpensive and safer than the use of gas or solid chlorine. All forms of chlorine are widely used despite their respective drawbacks. One drawback is that chlorine from any source reacts with natural organic compounds in the water to form potentially harmful chemical by-products trihalomethanes (THMs) and haloacetic acids (HAAs), both of which are carcinogenic in large quantities and regulated by the United States Environmental Protection Agency (EPA). The formation of THMs and haloacetic acids may be minimized by effective removal of as many organics from the water as possible prior to chlorine addition. Although chlorine is effective in killing bacteria, it has limited effectiveness against protozoans that form cysts in water (Giardia lamblia and Cryptosporidium, both of which are pathogenic).

- Chlorine dioxide is another faster-acting disinfectant. It is, however, relatively rarely used, because in some circumstances it may create excessive amounts of chlorite, which is a by-product regulated to low allowable levels in the United States. Chlorine dioxide is made in water and added/used in water to avoid gas handling problems; chlorine dioxide gas accumulations may spontaneously detonate.

- Chloramines are another chlorine-based disinfectant. Although chloramine is not as strong of an oxidant it does provide a longer-lasting residual than free chlorine, and it won't form THMs or haloacetic acids. It is possible to convert chlorine to chloramine by adding ammonia to the water after addition of chlorine: The chlorine and ammonia react to form chloramine. Water distribution systems disinfected with chloramines may experience nitrification, wherein ammonia is used a nutrient for bacterial growth, with nitrates being generated as a byproduct.

- Ozone (O3) is a relatively unstable molecule "free radical" of oxygen which readily gives up one atom of oxygen providing a powerful oxidising agent which is toxic to most waterborne organisms. It is a very strong, broad spectrum disinfectant that is widely used in Europe. It is an effective method to inactivate harmful protozoans that form cysts. It also works well against almost all other pathogens. Ozone is made by passing oxygen through ultraviolet light or a "cold" electrical discharge. To use ozone as a disinfectant, it must be created on-site and added to the water by bubble contact. Some of the advantages of ozone include the production of relatively fewer dangerous by-products (in comparison to chlorination) and the lack of taste and odour produced by ozonation. Although fewer by-products are formed by ozonation, it has been discovered that the use of ozone produces a small amount of the suspected carcinogen bromate, although little bromine should be present in treated water. Another of the main disadvantages of ozone is that it leaves no disinfectant residual in the water. Ozone has been used in drinking water plants since 1906 where the first industrial ozonation plant was built in Nice, France. The U.S. Food and Drug Administration has accepted ozone as being safe; and it is applied as an anti-microbiological agent for the treatment, storage, and processing of foods.

- UV radiation (light) is very effective at inactivating cysts, as long as the water has a low level of colour so the UV can pass through without being absorbed. The main disadvantage to the use of UV radiation is that, like ozone treatment, it leaves no residual disinfectant in the water. Because neither ozone nor UV radiation leaves a residual disinfectant in the water, it is sometimes necessary to add a residual disinfectant after they are used. This is often done through the addition of chloramines, discussed above as a primary disinfectant. When used in this manner, chloramines provide an effective residual disinfectant with very little of the negative aspects of chlorination.

- Hydrogen peroxide is another disinfectant. It works similar to ozone, yet activators as formic acid are to be added to increase the working of this chemical substance. It also has the disadvantages that it is slow-working, phytotoxic in high dosage, and decreases the PH of the water it purifies.

Additional treatment options

- Fluoridation: in many areas fluoride is added to water for the purpose of preventing tooth decay. This process is referred to as water fluoridation. Fluoride is usually added after the disinfection process. In the United States, fluoridation is usually accomplished by the addition of hexafluorosilicic acid, which decomposes in water, yielding fluoride ions.

- Water conditioning: This is a method of reducing the effects of hard water. Hardness salts are deposited in water systems subject to heating because the decomposition of bicarbonate ions creates carbonate ions which crystalise out of the saturated solution of calcium or magnesium carbonate. Water with high concentrations of hardness salts can be treated with soda ash ( sodium carbonate) which precipitates out the excess salts, through the common-ion effect, producing calcium carbonate of very high purity. The precipitated calcium carbonate is traditionally sold to the manufacturers of toothpaste. Several other methods of industrial and residential water treatment are claimed (without general scientific acceptance) to include the use of magnetic or/and electrical fields reducing the effects of hard water.

- Plumbosolvency reduction: In areas with naturally acidic waters of low conductivity (i.e surface rainfall in upland mountains of igneous rocks), the water may be capable of dissolving lead from any lead pipes that it is carried in. The addition of small quantities of phosphate ion and increasing the pH slightly both assist in greatly reducing plumbo-solvency by creating insoluble lead salts on the inner surfaces of the pipes.

- Radium Removal: Some groundwater sources contain radium, a radioactive chemical element. Typical sources include many groundwater sources north of the Illinois River in Illinois. Radium can be removed by ion exchange, or by water conditioning. The back flush or sludge that is produced is, however, a low-level radioactive waste.

- Fluoride Removal: Although fluoride is added to water in many areas, some areas of the world have excessive levels of natural fluoride in the source water. Excessive levels can be toxic or cause undesirable cosmetic effects such as staining of teeth. One method of reducing fluoride levels is through treatment with activated alumina.

Other water purification techniques

Other popular methods for purifying water, especially for local private supplies are listed below. In some countries some of these methods are also used for large scale municipal supplies. Particularly important are distillation (de-salination of seawater) and reverse osmosis.

- Boiling: Water is heated hot enough and long enough to inactivate or kill micro-organisms that normally live in water at room temperature. Near sea level, a vigorous rolling boil for at least one minute is sufficient. At high altitudes (greater than two kilometers or 5000 feet) three minutes is recommended. In areas where the water is "hard" (that is, containing significant dissolved calcium salts), boiling decomposes the bicarbonate ions, resulting in partial precipitation as calcium carbonate. This is the "fur" that builds up on kettle elements, etc., in hard water areas. With the exception of calcium, boiling does not remove solutes of higher boiling point than water and in fact increases their concentration (due to some water being lost as vapour). Boiling does not leave a residual disinfectant in the water. Therefore, water that has been boiled and then stored for any length of time may have acquired new pathogens.

- Granular Activated Carbon filtering: GAC, a form of activated carbon with a high surface area, absorbs many compounds including many toxic compounds. Water passing through activated carbon is commonly used in municipal regions with organic contamination, taste or odours. Many household water filters and fish tanks use activated carbon filters to further purify the water. Household filters for drinking water sometimes contain silver to release silver ions which have an anti-bacterial effect.

- Distillation involves boiling the water to produce water vapour. The vapour contacts a cool surface where it condenses as a liquid. Because the solutes are not normally vaporised, they remain in the boiling solution. Even distillation does not completely purify water, because of contaminants with similar boiling points and droplets of unvaporised liquid carried with the steam. However, 99.9% pure water can be obtained by distillation. Distillation does not confer any residual disinfectant and the distillation apparatus may be the ideal place to harbour Legionnaires' disease.

- Reverse osmosis: Mechanical pressure is applied to an impure solution to force pure water through a semi-permeable membrane. Reverse osmosis is theoretically the most thorough method of large scale water purification available, although perfect semi-permeable membranes are difficult to create. Unless membranes are well-maintained, algae and other life forms can colonize the membranes.

- Ion exchange: Most common ion exchange systems use a zeolite resin bed to replace unwanted Ca2+ and Mg2+ ions with benign (soap friendly) Na+ or K+ ions. This is the common water softener.

- Electrodeionization: Water is passed between a positive electrode and a negative electrode. Ion selective membranes allow the positive ions to separate from the water toward the negative electrode and the negative ions toward the positive electrode. High purity deionized water results. The water is usually passed through a reverse osmosis unit first to remove non-ionic organic contaminants.

- The use of iron in removing arsenic from water. See Arsenic contamination of groundwater.

- Direct contact membrane distillation (DCMD). Applicable to desalination. Heated seawater is passed along the surface of a hydrophobic polymer membrane. Evaporated water passes from the hot side through pores in the membrane into a stream of cold pure water on the other side. The difference in vapour pressure between the hot and cold side helps to push water molecules through.

- Gas hydrate crystals centrifuge method. If carbon dioxide gas is mixed with contaminated water at high pressure and low temperature, gas hydrate crystals will contain only clean water. This is because the water molecules bind to the gas molecules at molecule level. The contaminated water is in liquid form. A centrifuge may be used to separate the crystals and the concentrated contaminated water.

Portable water purification

Portable techniques for purifying water are used for hiking, camping etc. or for use in rural areas or emergency situations. Common techniques include boiling, disinfection with tablets or ultra-filtration using a small hand pump.

In addition to this "portable water purification" may also include residential, commercial or industrial water treatment systems that are regenerated off site (by others). These systems are most commonly used for deionization in industrial applications or softening for residential applications. Also known as Service Deionization (SDI), industrial companies use these portable systems for a variety of reasons. Most commonly, the user has a small application and can not justify the expense of having regenerant chemicals such as sulfuric or hydrochloric acid and sodium hydroxide on site for safety and or manpower reasons. There may be waste water discharge limitations that make owning and operating an in-house deionizer (also known as a demineralizer) too expensive in comparison to the outsourcing of regeneration.

In residential applications a water treatment company delivers portable softener exchange tanks to a household. These softener tanks treat all or some of the water entering the household and remove hardness minerals. They are exchanged on a pre-determined schedule so the household has softened water on a on a continual basis. Although not as cost effective as owning a water softener, portable water softeners require no maintenance by the home owner; furthermore there is no discharge of brine to septic or municipal waste treatment systems.

Water purification for hydrogen production

For the small scale production of hydrogen, water purifiers are installed to prevent formation of minerals on the surface of the electrodes and to remove organics and chlorine from utility water. First, the water passes through a 20 micrometre interference ( mesh or screen filter) filter to remove sand and dust particles, then a charcoal filter using activated carbon to remove organics and chlorine and, finally, a de-ionizing filter to remove metallic ions. Testing can be done before and after the filter to verify the proper removal of barium, calcium, potassium, magnesium, sodium and silicon.

Another method that is used is reverse osmosis.

Safety and controversies

There has been controversy over the fluoridation of water since the 1930s, when the benefits to dental health were first claimed. There is evidence that excessive concentrations of fluorides can make teeth, and bones, more brittle and easily damaged / broken. Fluoridation is banned in many countries.

Water supplies have sometimes been the subject of concerns over terrorism or actual terrorist threats.

Accidents have also been known to happen. In April, 2007, the water supply of Spencer, Massachusetts became contaminated with excess sodium hydroxide (lye) when its treatment equipment malfunctioned.