Managing control is essential to making sure that a process or system is running effectively within an organization. There are sometimes barriers to testing, measuring, communicating, or observing how effectively a system or process is running. These barriers can reduce the efficacy of the organization, not only in the process being controlled but also in the controlling process. Barriers to organizational control can include scarcity of resources, inaccurate measurements of the process, improper information flow, and incorrect analyses.

Resource Scarcity

Managing control typically requires a number of resources. These resources include supervisory staff, skilled specialists, tools to measure the control of the system, and often complex statistical software and other tracking technologies. A lack of any (or all) of these crucial inputs can drastically reduce the ability of the control team to collect and communicate their findings. This under-funding of the control system creates resource scarcity for the process.

Inaccurate Measurement

Inaccurate measurement while managing control can happen for a number of different reasons, including:

- Inaccurate measuring devices

- Misunderstanding of the measurement process by staff

- Inaccurate or misleading measurement processes

- Lack of staff training to determine how to measure the control process

These issues can result in inaccurate measurements, which can make the control process more of a danger to the evolution of the process than an asset. All measurement tests need to be tested themselves; an understanding of best practices in taking measurements is critical in project managment.

Information Flow Issues

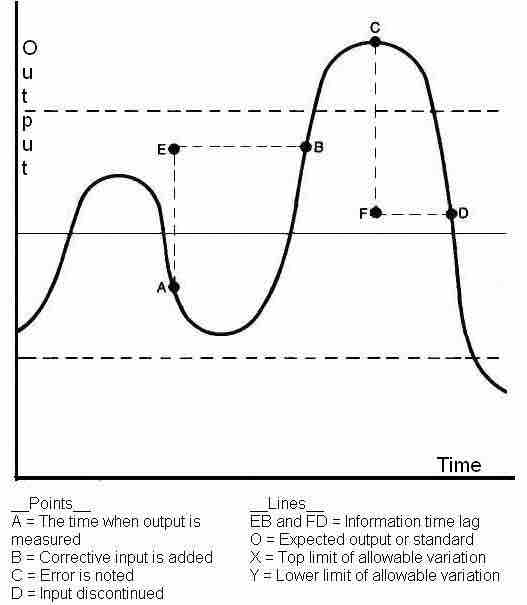

A particularly complex barrier to offset is information flow. Information is collected at one point in the process and analyzed contextually at another. This time lag in information flow can misdirect management to problems at the wrong time in the sequence. Ensuring timely discovery and reporting of measurements mitigates this risk.

Oscillation and feedback

Output changes over time, creating room for error in the measurement process. Because there is necessarily a delay between measuring data, analyzing the data and identifying a problem, and ultimately implementing a solution, solutions may be implemented after the problem is no longer relevant (as shown in the graph—output is already improving before the solution for the prior dip in output is implemented). Timely discovery and reporting of measurements helps minimize this problem of delay in information flow.

Even with adequate resources to manage control and accurate measurement and information flow, barriers to analyzing data can still appear. These can be introduced by human error or software error. It is useful to think statistically: a good manager will consider a 99% confidence interval that a given process is underperforming as sufficient evidence to take action to improve it, despite the fact that one time out of a hundred the issue will not be significant. Even one failure out of one hundred adds up in an organization with thousands of processes to monitor.

A lack of resources, inaccurate measurements, information flow errors, and incorrect analyses can all result in significant barriers to managing control of a process or system. Managers should be aware of these barriers and do their best to avoid them through training and accuracy.